Thermographic Report - Anomaly Types and Root Causes

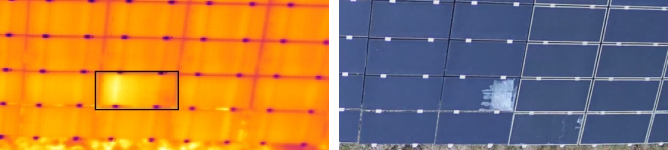

Heated Module

A module showing anomalous heating across the entirety of its surface. Heated modules can have an intrinsic root cause, or heating can occur secondary to an extrinsic root cause. A common extrinsic root cause is 'string heating', where all modules in an electrical string are affected by a problem at the string level. String heating, in turn, may have an obvious visible cause (e.g. arboreal shading), or may require further investigation (e.g. 'open circuit string').

Root Cause

- Individual module heating (Intrinsic)

- No identifiable cause on RGB, may be:

- 'Open circuit' module

- Junction box issue

- Activation of all three diodes

- Damaged module (may be visible in RGB)

- String Heating - a chain of heated modules corresponding to a string

- String heating - no identifiable cause (typically “open circuit” string).

- String heating - secondary to arboreal shading.

- String heating - secondary to permanent shading.

- String heating - secondary to damaged module (a single damaged module in a string can cause the whole string to heat).

- String heating - secondary to missing module (a missing module can cause the whole string to heat if the string has not been reconnected correctly).

- Inverter-level anomaly - a large group of heated modules corresponding to an inverter area.

- An inverter fault is causing a large area of modules to heat.

Notes

- More details on the root cause classification of Heated Module anomalies (and the changes made to this in July 2022) are available in the following document: https://abovesurveying.sharepoint.com/:w:/s/Publicsupportdocs/EZP5kk53EvVBhswKonaYURsB21itD9xQLaP4YccjuWeysg?e=UEtYW7

- Heated Modules are recorded regardless of temperature gradient relative to 'normal' module. The reference temperature will be recorded from the nearest unaffected module, which may not be within the image

- The temperature gradient is not necessarily an indicator of power loss.

- For string heating and inverter-level heating, only the first 3-5 exemplar heated modules are shown in the image.

- Occasionally module heating can occur across all the modules in a string, but in a heterogeneous 'multiple hot cell' pattern (rather than uniformly). This is typically caused by reverse polarity on the string, or may occur following lightning strike.

- The reason that an open circuit substring, module or string is hotter than a normally working substring, module or string is that a proportion of the solar energy (radiation) hitting the surface (the cells) is no longer being converted into electricity and is therefore being absorbed as heat. The reason the gradient is relatively constant (approximately 4 to 10°C) in most given settings, is because the impact of the ambient temperature is theoretically neutral as both the working and the none working module are experiencing the same ‘base heat’ from the ambient air.

Heated Substring

One-third or two-thirds of the module appear heated (or other proportions, in newer module types e.g. half-cut modules).

Root Cause

- Appropriate activation of diode (diode bypassing bad cells)

- Malfunctioning diode

- Loose connection

- Lightning strike

- If the cause of the diode activation is visible and appropriate (e.g. soiling/hot spot), then the primary cause (the hot spot) is recorded, and the substring heating is NOT regarded as an anomaly.

- If there is no obvious cause of diode activation, then a heated substring is recorded, regardless of temperature gradient. Further on-site investigation is required to differentiate appropriate vs anomalous substring heating, since this cannot be determined from UAV thermographic/RGB inspection alone.

- Traditional 60- and 72-cell silicon module designs consist of three diodes, each protecting one-third of the module. Newer module designs (e.g. half-cut cell modules) may have 6 or more substring areas, which may be connected in more complex (series/parallel) configurations. These are currently also recorded as 'heated substring', but this is subject to regular review and more sophisticated anomaly types may be introduced.

- The reason that an open circuit substring, module or string is hotter than a normally working substring, module or string is that a proportion of the solar energy (radiation) hitting the surface (the cells) is no longer being converted into electricity and is therefore being absorbed as heat. The reason the gradient is relatively constant (approximately 4 to 10°C) in most given settings, is because the impact of the ambient temperature is theoretically neutral as both the working and the none working module are experiencing the same ‘base heat’ from the ambient air.

Notes

Hot Spot

Single heated area or cell.

Root Cause

- Commonly identified from UAV inspections:

- Soiling

- Arboreal shading

- Permanent shading

- Damaged module

- Usually only identifiable on further investigation:

- Cell mismatch

- Shunted cell

- Cracked cell

Notes

- A hot spot is considered significant and recorded if ΔTm ≥ 4°C on silicon technology modules and ΔTm ≥ 2°C on thin-film technology modules.

- The higher the temperature gradient, the higher the associated power loss

Multiple Hot Cells

More than one heated cell on a single module.

Root Cause

- Damaged module

- Soiling

- Arboreal shading

- Permanent shading

- Cell mismatch

- Cracked glass

- Combiner box anomaly

- Inverter anomaly

Notes

- Multiple hot cells are considered significant and recorded ifΔTm ≥ 4°C on silicon technology modules and ΔTm ≥ 2°C on thin-film technology modules.

Heated Junction Box

We record a heated junction box when it is significantly hotter than the average of the site. It is normal for the junction box to be slighter warmer than the module itself.

Root Cause

- Junction box issue

- Loose connection

- Corrosion

- Diode activated

Notes

- Junction box heating is considered significant and recorded if ΔTm ≥ 7°C compared to a normal neighbouring junction box.

- Heated Junction Boxes do not necessarily contribute to lost output, but in some circumstances can be a warning of problems to come

SEHP

String-end heating pattern (SEHP) – occurring as a repeated pattern across the site or in large areas, 'SEHP' is our term for a pattern of heating that might indicate onset of PID.

Root Cause

- PID (potential-induced degredation)

Notes

- 'SEHP' is our term for a pattern of heating that might indicate PID

- SEHP is recorded regardless of temperature gradient

- Aligned with negative string end where we know the stringing pattern

Heated Hypercell

A heated hypercell is a specific anomaly type seen in certain 'shingle-cell' type solar modules. These modules are typically divided into 18 hypercells, each of which can become heated.

Root Cause

- Presumed to be caused by shingle-cell adhesive failure.

Missing Module

Used when a module is missing, but not by design (as determined by the provided CAD file).

Notes

- The reference and target (peak) temperatures are set manually set so that ΔTm = 0°C

Tracker Fault

Tracker-array is not correctly tracking the sun.

Root Cause

- Alignment failure

- Mechanism failure

- The reference and target (peak) temperatures are set manually set so that ΔTm = 0°C

Notes

Visual (thin-film modules)

A clear anomaly can be seen in the RGB image of a thin-film module.

Root Cause

- Delamination

- Damaged Module (Cracks)

- Surface scratches

- A visual anomaly is used in our specialist thin-film service, to indicate clear visible damage on a module, which doesn't necessarily cause a thermal anomaly

- Visual anomalies are not generally used in non-thin-film inspections, except in the case of extreme visible damage that we think is important to highlight to the client.

Notes

Related Articles

Thermographic Report - Survey Compare

Introduction The Survey Compare tool enables you to: Compare up to 3 inspections Have a high-level anomaly comparison Look at the evolution per module Get a detailed breakdown for each status The Survey Compare page has been designed to match the ...Thermographic Report - Anomaly Groups

Health & Safety Impact Items that may pose an immediate risk or liability to the plants health and safety requirements. Visibly Damaged Modules Heated Substrings & Hot Spots Elevated Hot Spot ΔTm Results String End Heating Pattern (SEHP) which can be ...Thermographic Report - Advanced Power Loss Estimation

The sophisticated Power Loss Estimation feature available on SolarGain enables you to: Better understand the impact anomalies found during thermal inspections have on the performance of your solar site Focus on solving issues on the lowest performing ...Thermographic Report - Glossary

Acronym/Jargon Explanation AGL Above ground level (Altitude) ATL Above take-off level (Altitude) CAD Computer-aided design [document] Here, generally used to refer to schematic drawings of the layout of a solar plant. Delta-Tm (ΔTm) The measured ...Visual Evidence Report

List of Reports There are 2 ways to find the visual report in SolarGain. Open the list through the project Dashboard Open through the Left-Hand Navigation Bar Filter the list of reports The user is able to filter the list of reports by combining ...